The result of impregnation may be influenced by different factors, for example, the wood species, humidity and the process of impregnation itself. Therefore there are several treatment classes. We use only class 3 and 4:

Class 1

For the use above the ground, in dry places under the roof. There is a risk of insects infestation.

Class 2

For the use above the ground, in dry places under the roof, but with the possible affect of moisture.

Class 3

For the use above the ground, in wet places without the roof (on the terraces). May be used in the ground which is not particularly wet.

Class 4

In the direct contact with water and in the particularly wet ground.

The posts stored at out warehouse mostly are of standard quality – undried and impregnated with treatment class 3. The lifetime of such posts, depending on the diameter and place of use, is 3-10 years. The thicker is the post and the dryer and sandier is the ground, the longer will be the lifetime.

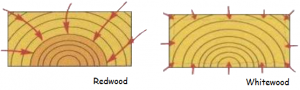

In order to ensure the lifetime up to 20 years, the posts used for pastures, fences, fastening of banks or other needs should be impregnated with treatment class 4. In order to perform the qualitative impregnation with treatment class 4, the following conditions should be observed:

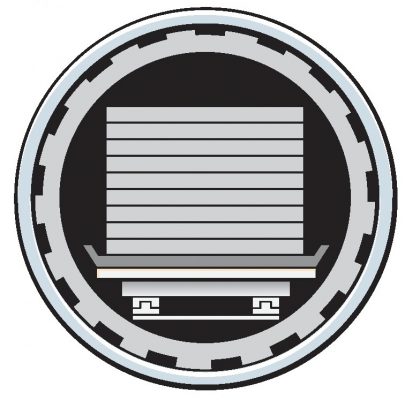

- the posts should be from the pine species;

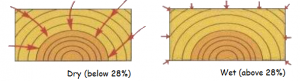

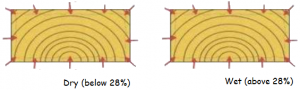

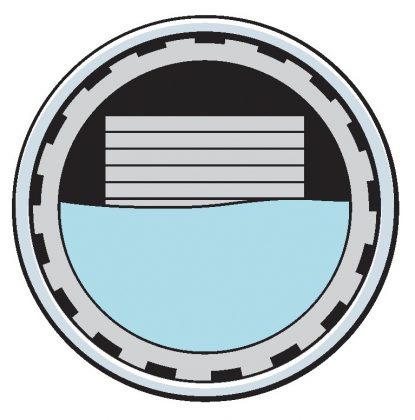

- the posts should be dried before the impregnation – moisture content should not exceed 28%;

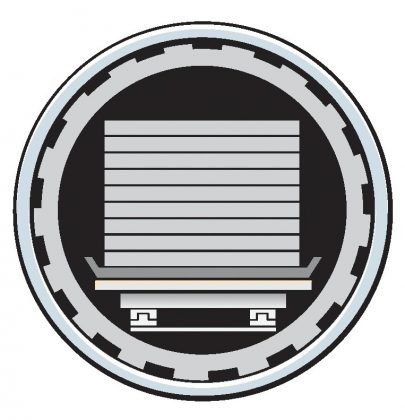

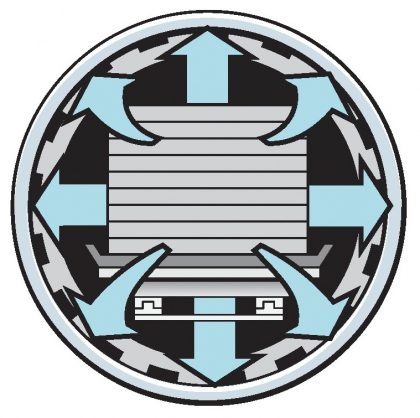

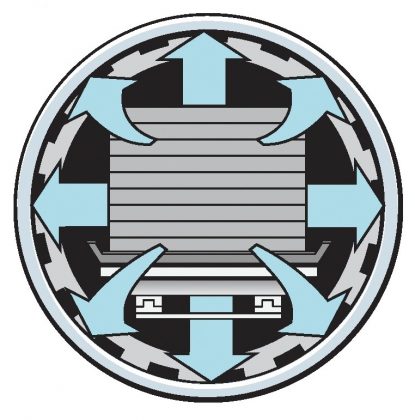

- during the impregnation the protective agent should be considerably pressed into until the core until it penetrates it at the full dosage.